Processing Center

Processing Center

All-In-One (AIO)

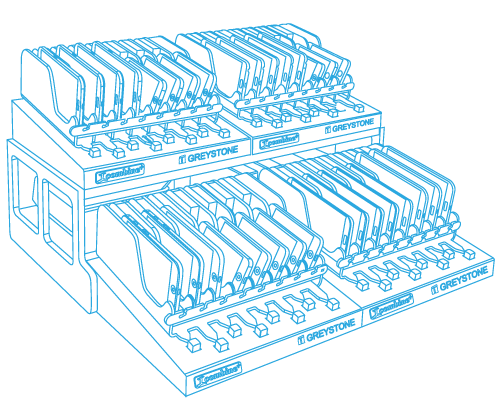

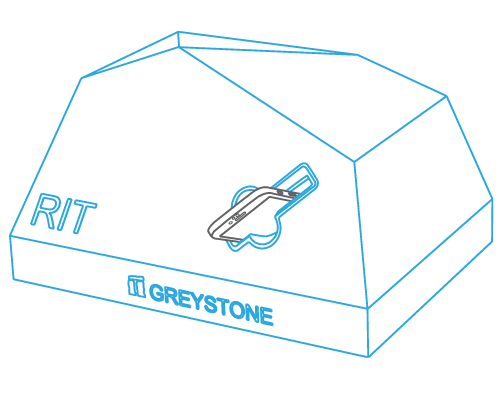

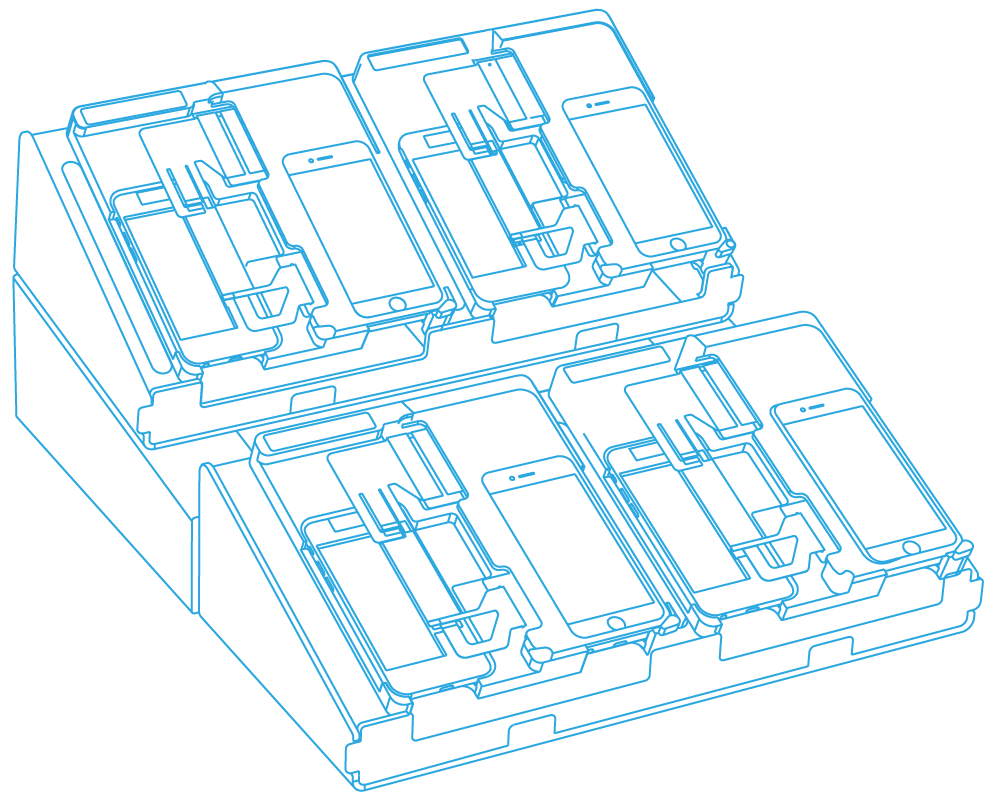

Relying on powerful OCR algorithms to convert captured images to machine text and data. The RIT machine receives device information without requiring connection to a computer or the device to power on. This innovative system is capable of reading the Human readable information on the back of a mobile device, then parsing the information out to a computer in machine language. You no longer need to read an IMEI on the back of a device and type it into a computer. The data is analyzed and presented in industry accepted formats. The RIT system also reads bar codes in any orientation adding to the versatility of this system. You may even connect a mobile device to the KIT system to read the internal information. The KIT has barcode scanner emulation with programmable keystroke output via USB connection. The KIT provides complete productivity reporting, which is available on our cloud based Dashboard.

Receiving Imaging Technology

Relying on powerful OCR algorithms to convert captured images to machine text and data. The RIT machine receives device information without requiring connection to a computer or the device to power on. This innovative system is capable of reading the Human readable information on the back of a mobile device, then parsing the information out to a computer in machine language. You no longer need to read an IMEI on the back of a device and type it into a computer. The data is analyzed and presented in industry accepted formats. The RIT system also reads bar codes in any orientation adding to the versatility of this system. You may even connect a mobile device to the KIT system to read the internal information. The KIT has barcode scanner emulation with programmable keystroke output via USB connection. The KIT provides complete productivity reporting, which is available on our cloud based Dashboard.

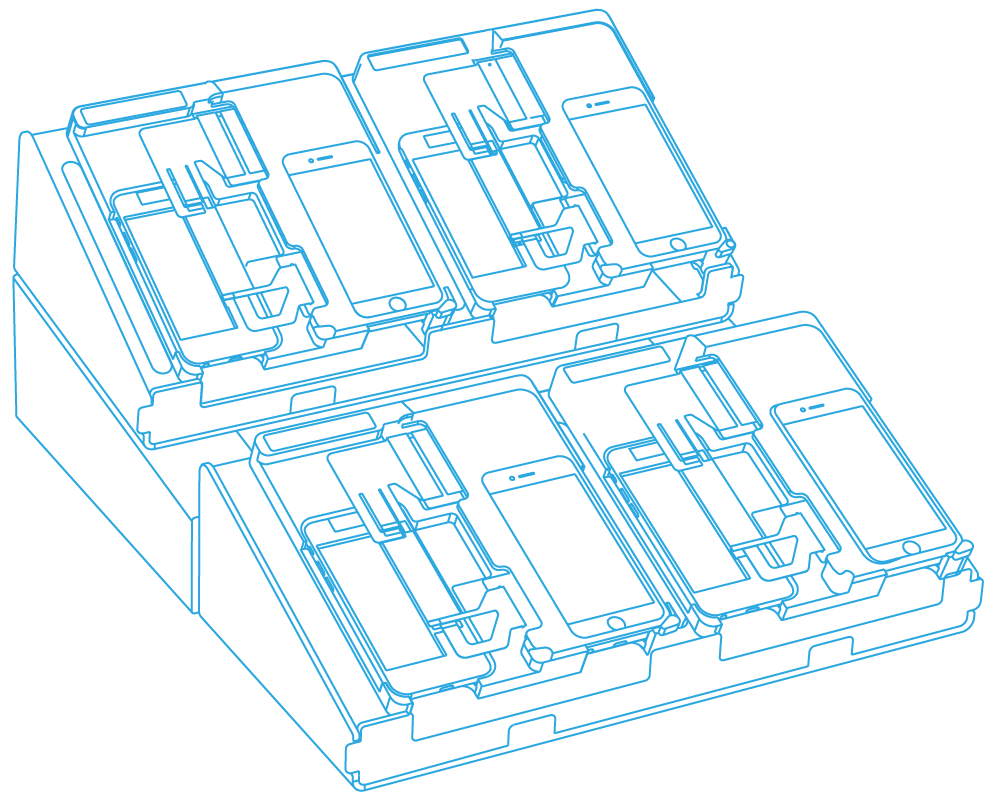

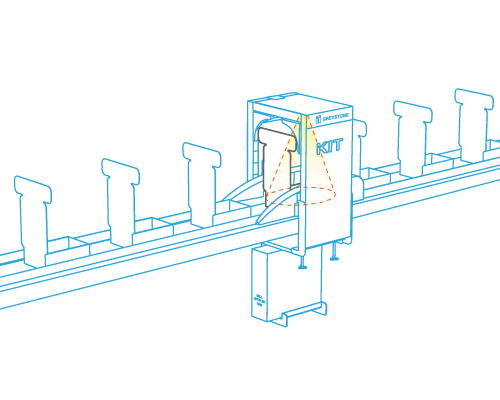

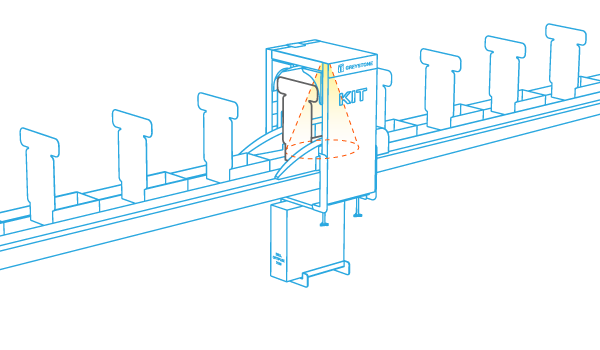

KIT is a Quality Control (QC) system utilizing machine vision to reduce the number of errors encountered from products not placed into boxes. The use of a real time camera to detect if an item is in the box allows for “on-the-fly” QC of the box contents as it is carried along on a conveyor belt. This system is capable of tracking the quantity of product by Stock Keeping Unit (SKU) consumed as the build is progressing. Optimization of the order fulfillment process is achieved by checking the contents of the package before the lid is sealed. Versatility of the systems allows it to be used on moving conveyor lines or in a stand-alone packing station. You may generate various production reports by retrieving data that is collected in our easy to use Dashboard. The system is fully integrated, small, convenient, easy to use and accurate.

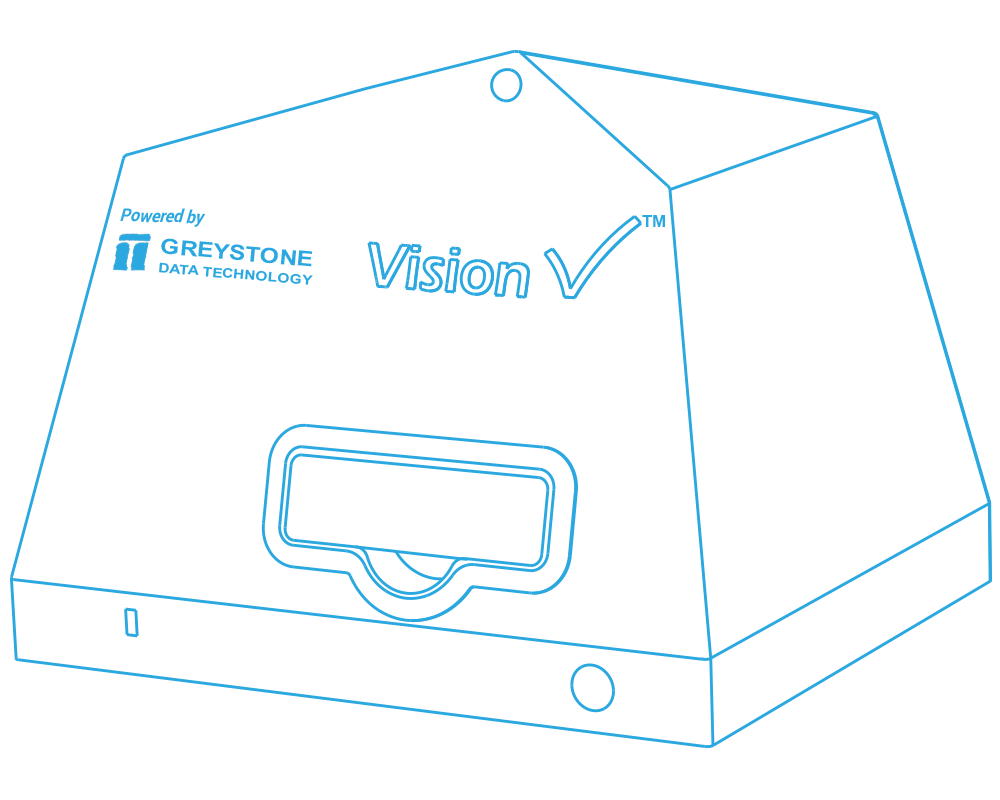

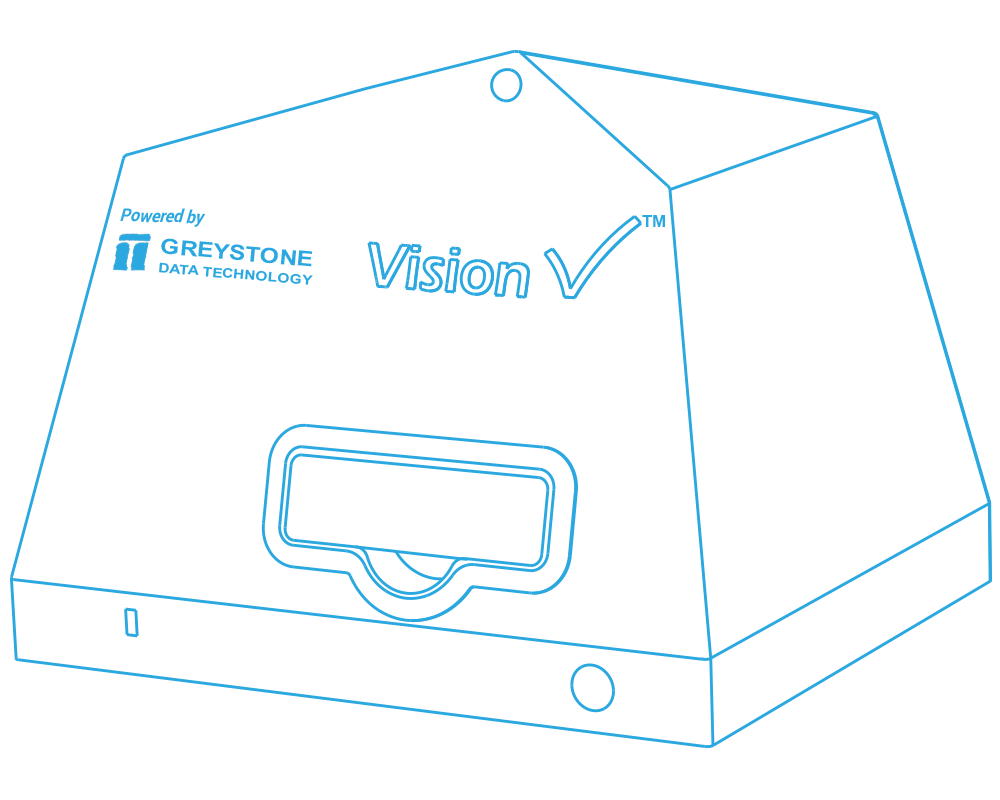

Kitting Imaging Technology

KIT is a Quality Control (QC) system utilizing machine vision to reduce the number of errors encountered from products not placed into boxes. The use of a real time camera to detect if an item is in the box allows for “on-the-fly” QC of the box contents as it is carried along on a conveyor belt. This system is capable of tracking the quantity of product by Stock Keeping Unit (SKU) consumed as the build is progressing. Optimization of the order fulfillment process is achieved by checking the contents of the package before the lid is sealed. Versatility of the systems allows it to be used on moving conveyor lines or in a stand-alone packing station. You may generate various production reports by retrieving data that is collected in our easy to use Dashboard. The system is fully integrated, small, convenient, easy to use and accurate.

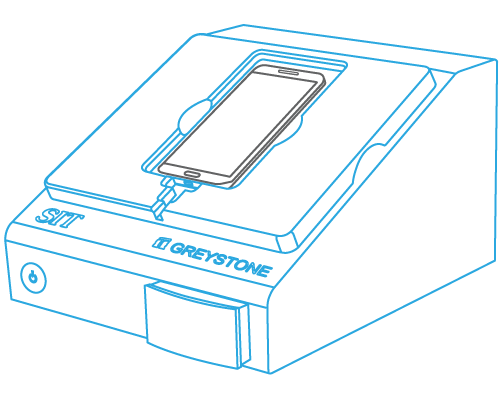

The SIT is a security machine that helps reduce stolen and missing devices from processing facilities. It pairs the employee ID card with the internal IMEI of the employee’s electronic devices. This prevents board swapping from customer devices into employee devices. Our simple database system tracks all employee devices coming in and out of the facilities. Visitors can be tracked and removed from the database when they turn in their visitor badge. The system is fully integrated and works through an iPad interface. Small, convenient, easy to use and accurate.

Security Imaging Technology

The SIT is a security machine that helps reduce stolen and missing devices from processing facilities. It pairs the employee ID card with the internal IMEI of the employee’s electronic devices. This prevents board swapping from customer devices into employee devices. Our simple database system tracks all employee devices coming in and out of the facilities. Visitors can be tracked and removed from the database when they turn in their visitor badge. The system is fully integrated and works through an iPad interface. Small, convenient, easy to use and accurate.

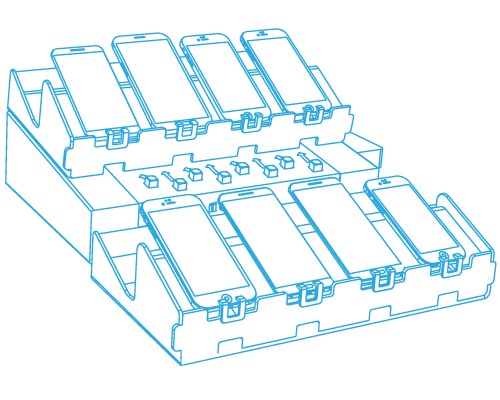

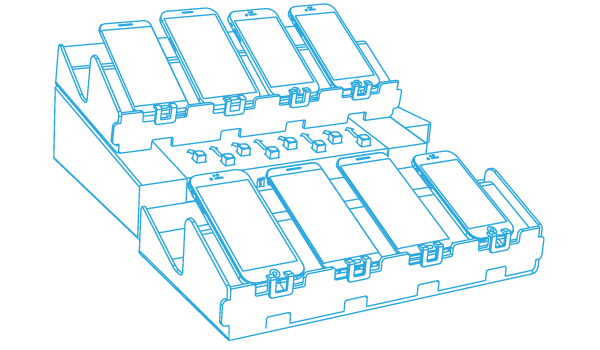

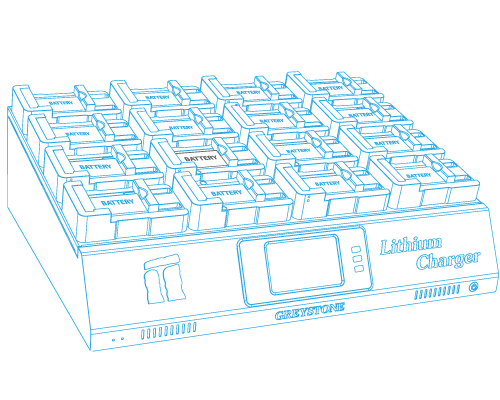

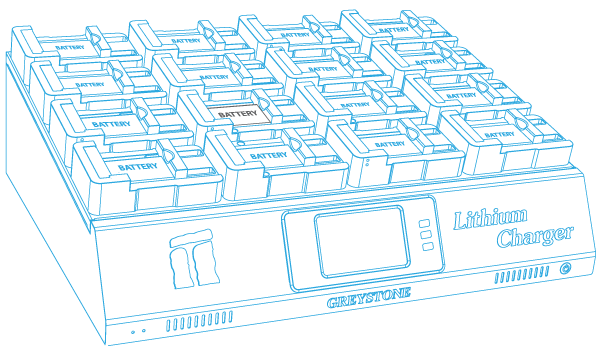

The Lithium Charger is designed to handle up to 16 batteries at one time. Batteries can all be the same or mixed models, each universal port will charge the battery independent of the other universal ports. Batteries used in today’s electronic devices have a larger capacity, the Lithium Charger will be able to handle these batteries up to 6000 mAh. The unique patented battery holder is designed to be easy to use and flexible. A “wake up” feature will put a quick high current charge on batteries that are “exhausted” or completely run down, bringing the battery back to life. The target charge percentage is selectable to support your unique charging needs and times. Versatility and charge capacity of the Lithium Charger sets it apart from all other chargers on the market today.

Lithium Charger

The Lithium Charger is designed to handle up to 16 batteries at one time. Batteries can all be the same or mixed models, each universal port will charge the battery independent of the other universal ports. Batteries used in today’s electronic devices have a larger capacity, the Lithium Charger will be able to handle these batteries up to 6000 mAh. The unique patented battery holder is designed to be easy to use and flexible. A “wake up” feature will put a quick high current charge on batteries that are “exhausted” or completely run down, bringing the battery back to life. The target charge percentage is selectable to support your unique charging needs and times. Versatility and charge capacity of the Lithium Charger sets it apart from all other chargers on the market today.

VisionCheck

PCB Tester