Repair Center

Repair Center

R&D engineers are responsible for designing commercial products, designing test equipment to support factory processes and design ERP system for the company.

Along with the capabilty of completing ownership of mechanical, electronic, and software design from conception and definition to finished product, including mechanical design, logic design, schematic design, pcb layout, firmware and driver design, software design, design validation and test design, component purchasing, and product assembly.

.jpg)

R&D Campus

R&D engineers are responsible for designing commercial products, designing test equipment to support factory processes and design ERP system for the company.

Along with the capabilty of completing ownership of mechanical, electronic, and software design from conception and definition to finished product, including mechanical design, logic design, schematic design, pcb layout, firmware and driver design, software design, design validation and test design, component purchasing, and product assembly.

Greystone VN (a wholly owned subsidiary of Greystone USA)’s 400,000 sq. ft. Repair Center is located in Ho Chi Minh City Vietnam and has been operating for over 13 years. It is located in a Free Trade Zone with on-site customs clearance with expansion capabilities up to 600,000 sq. ft. Our Repair Center is home to over 1,300 employees and holds many accreditations and certifications including: ISO 9001-2008 (Quality Management System), ISO 14001-2004 (Environment Management System), OHSAS 18001-2007 (Occupational Health and Safety Management System), CTPAT (Customs Trade Partnership Against Terrorism), EICC (Electronic Industry Citizenship Coalition), and R2-2013 (Electronics Repair and Recycling).

Our repair center is equipped with a clean room, many state of the art tools, and over 100 highly skilled engineers. Our capabilities include mobile device (iPhone, iPad, Samsung, LG, etc.) testing and remanufacturing to OEM ‘like new’ standards as well as hard disk testing, failure analysis, diagnosis, repair, data erasure, and more. We are also able to test, diagnose, and service PC, laptop, and server motherboards at the component level. Our Repair Center is also capable of repairing/refurbishing other devices such as MP3 players, game systems, and more.

GREYSTONE DATA SYSTEMS VIETNAM

62 Linh Trung Export Processing Zone 2

Binh Chieu Ward, Thu Duc District,

Ho Chi Minh City.

Greystone VN Repair Center

Greystone VN (a wholly owned subsidiary of Greystone USA)’s 400,000 sq. ft. Repair Center is located in Ho Chi Minh City Vietnam and has been operating for over 13 years. It is located in a Free Trade Zone with on-site customs clearance with expansion capabilities up to 600,000 sq. ft. Our Repair Center is home to over 1,300 employees and holds many accreditations and certifications including: ISO 9001-2008 (Quality Management System), ISO 14001-2004 (Environment Management System), OHSAS 18001-2007 (Occupational Health and Safety Management System), CTPAT (Customs Trade Partnership Against Terrorism), EICC (Electronic Industry Citizenship Coalition), and R2-2013 (Electronics Repair and Recycling).

Our repair center is equipped with a clean room, many state of the art tools, and over 100 highly skilled engineers. Our capabilities include mobile device (iPhone, iPad, Samsung, LG, etc.) testing and remanufacturing to OEM ‘like new’ standards as well as hard disk testing, failure analysis, diagnosis, repair, data erasure, and more. We are also able to test, diagnose, and service PC, laptop, and server motherboards at the component level. Our Repair Center is also capable of repairing/refurbishing other devices such as MP3 players, game systems, and more.

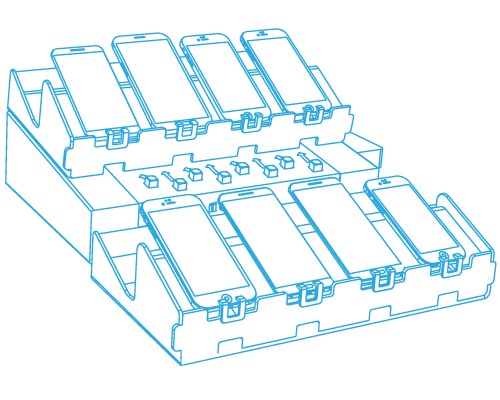

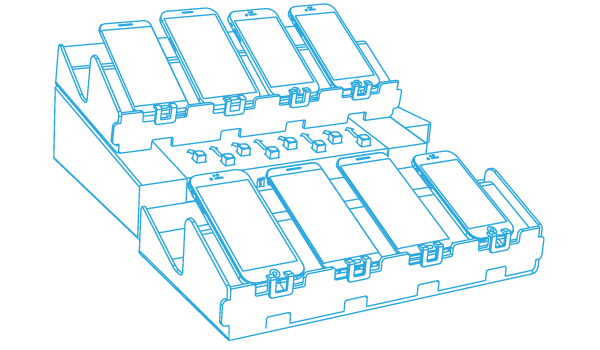

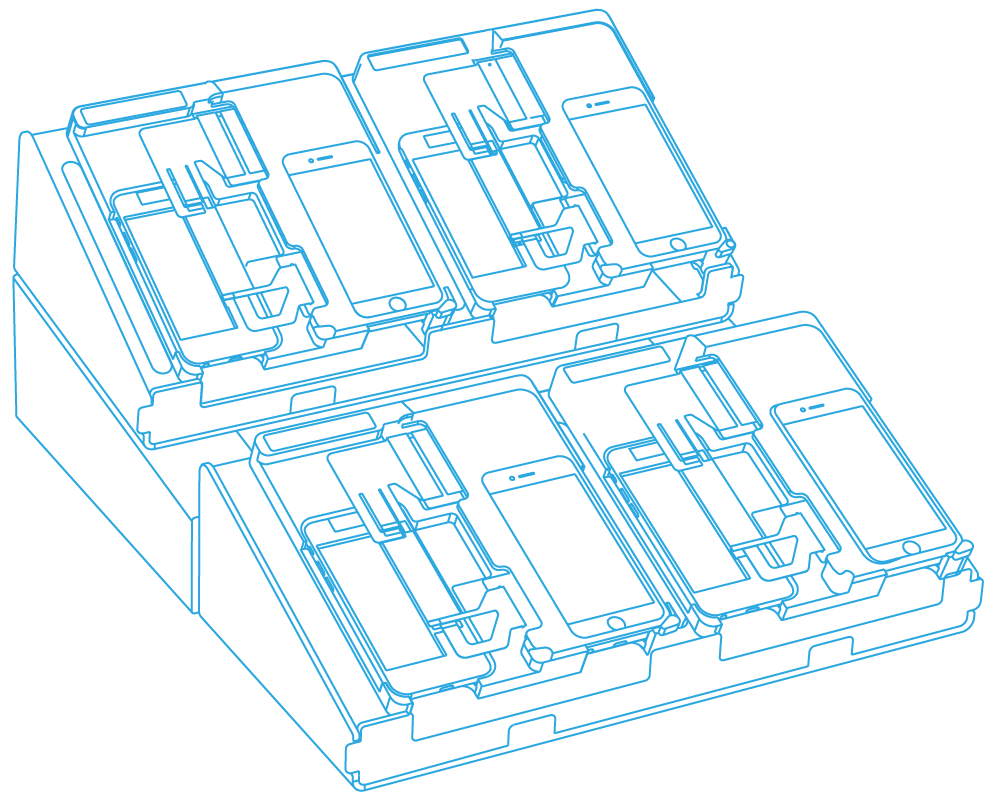

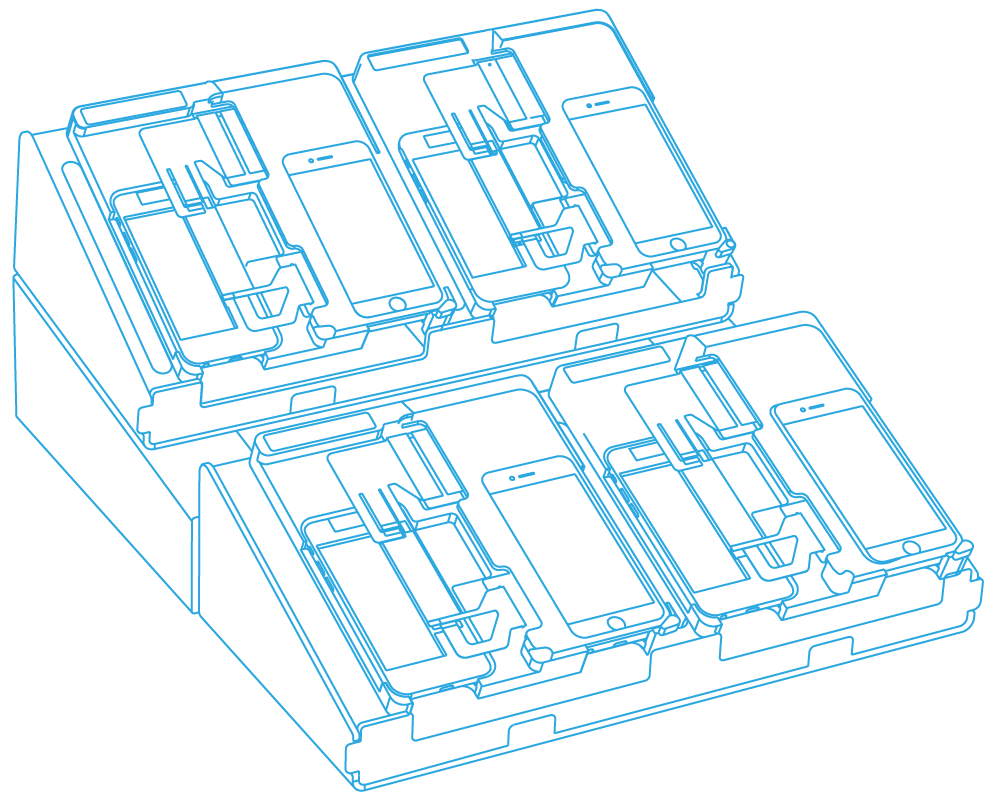

The AIO is an advanced all-inclusive mobile testing platform designed for use in warehouse or production environments. This system is very versatile and scalable for any size of operation. The AIO is able to receive mobile devices into your Warehouse Management System (WMS), test the full functionality of a mobile device, remove and sanitize all data from the mobile device with data erasure solution has been certified by ADISA. One machine does it all. All information about the device, tests, and content sanitization is maintained in an off-site database the customer may access at any time. This gives you end to end reporting of devices at the IMEI level. One computer can support up to 4 Icombine (hardware) modules. Each Icombine module can support up to 8 mobile devices at one time. Our system is the only system that can process your Android, Apple, BlackBerry and Windows devices all at the same time on the same Icombine module. No need for dedicated equipment or redundant computer systems. Supports over 1000 smartphone devices from every major manufacture.

All-In-One (AIO)

The AIO is an advanced all-inclusive mobile testing platform designed for use in warehouse or production environments. This system is very versatile and scalable for any size of operation. The AIO is able to receive mobile devices into your Warehouse Management System (WMS), test the full functionality of a mobile device, remove and sanitize all data from the mobile device with data erasure solution has been certified by ADISA. One machine does it all. All information about the device, tests, and content sanitization is maintained in an off-site database the customer may access at any time. This gives you end to end reporting of devices at the IMEI level. One computer can support up to 4 Icombine (hardware) modules. Each Icombine module can support up to 8 mobile devices at one time. Our system is the only system that can process your Android, Apple, BlackBerry and Windows devices all at the same time on the same Icombine module. No need for dedicated equipment or redundant computer systems. Supports over 1000 smartphone devices from every major manufacture.

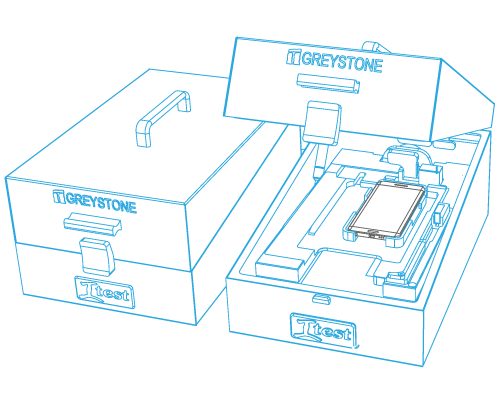

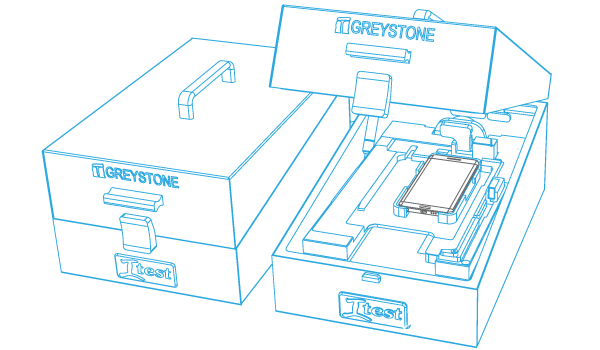

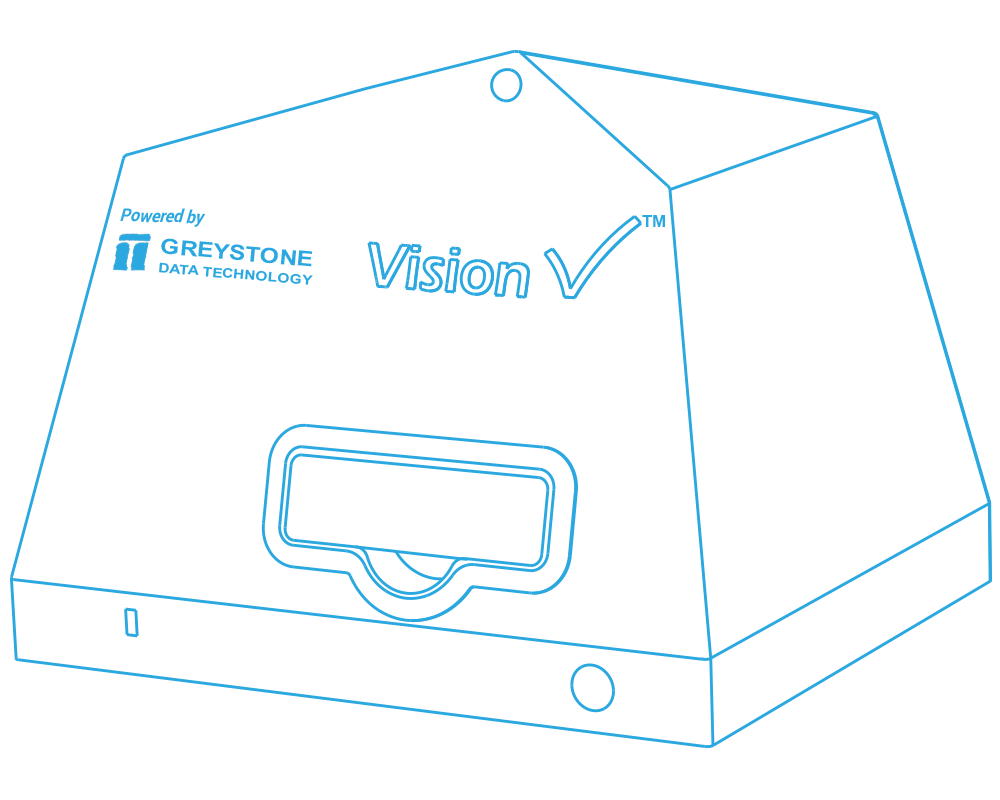

The Itest Chamber is a hardware technology developed to eliminate the need for manual functional tests on the mobile device. The Itest Chamber is a sturdy, compact unit that is capable of running extensive and automatic tests such as: Wi-Fi, Audio, proximity sensor, call signal functionality, and more. The capability of automatically testing these features on the mobile device will eliminate human error, and increase throughput of devices completed by the operator. After each device is processed it will give the operator a gauge on the functional status of the device.

Supports over 1000 smartphone devices from manufactures such as: Apple, Nokia, Samsung, LG, BlackBerry, Casio, HTC, Motorola, Pantech, Sanyo, Sharp, Sony Ericsson, and more.

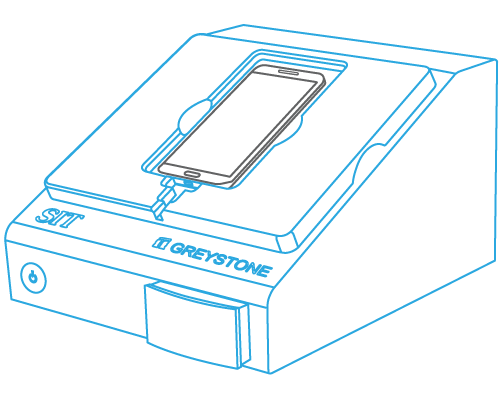

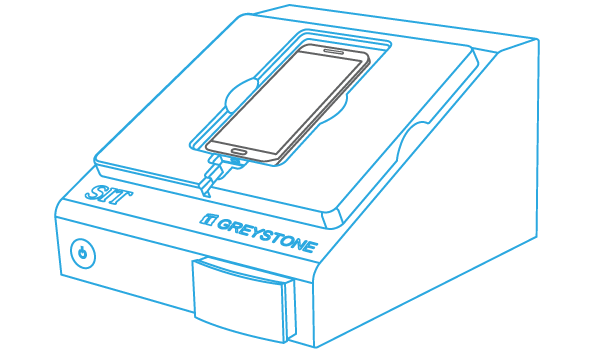

Itest Chamber

The Itest Chamber is a hardware technology developed to eliminate the need for manual functional tests on the mobile device. The Itest Chamber is a sturdy, compact unit that is capable of running extensive and automatic tests such as: Wi-Fi, Audio, proximity sensor, call signal functionality, and more. The capability of automatically testing these features on the mobile device will eliminate human error, and increase throughput of devices completed by the operator. After each device is processed it will give the operator a gauge on the functional status of the device.

Supports over 1000 smartphone devices from manufactures such as: Apple, Nokia, Samsung, LG, BlackBerry, Casio, HTC, Motorola, Pantech, Sanyo, Sharp, Sony Ericsson, and more.

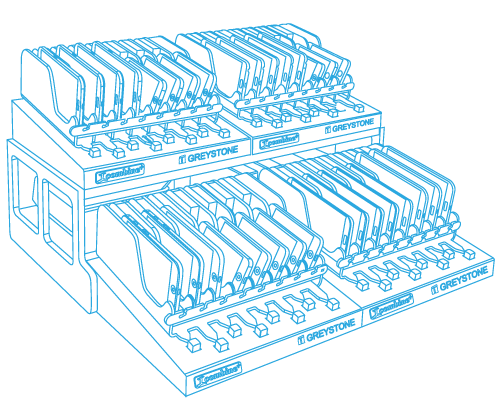

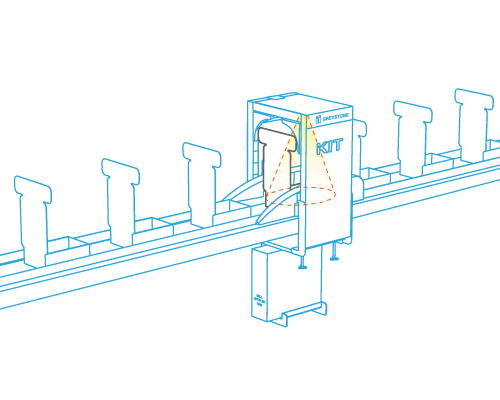

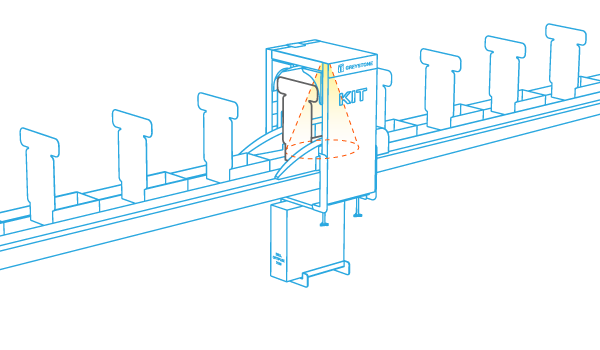

KIT is a Quality Control (QC) system utilizing machine vision to reduce the number of errors encountered from products not placed into boxes. The use of a real time camera to detect if an item is in the box allows for “on-the-fly” QC of the box contents as it is carried along on a conveyor belt. This system is capable of tracking the quantity of product by Stock Keeping Unit (SKU) consumed as the build is progressing. Optimization of the order fulfillment process is achieved by checking the contents of the package before the lid is sealed. Versatility of the systems allows it to be used on moving conveyor lines or in a stand-alone packing station. You may generate various production reports by retrieving data that is collected in our easy to use Dashboard. The system is fully integrated, small, convenient, easy to use and accurate.

Kitting Imaging Technology

KIT is a Quality Control (QC) system utilizing machine vision to reduce the number of errors encountered from products not placed into boxes. The use of a real time camera to detect if an item is in the box allows for “on-the-fly” QC of the box contents as it is carried along on a conveyor belt. This system is capable of tracking the quantity of product by Stock Keeping Unit (SKU) consumed as the build is progressing. Optimization of the order fulfillment process is achieved by checking the contents of the package before the lid is sealed. Versatility of the systems allows it to be used on moving conveyor lines or in a stand-alone packing station. You may generate various production reports by retrieving data that is collected in our easy to use Dashboard. The system is fully integrated, small, convenient, easy to use and accurate.

Security Imaging Technology

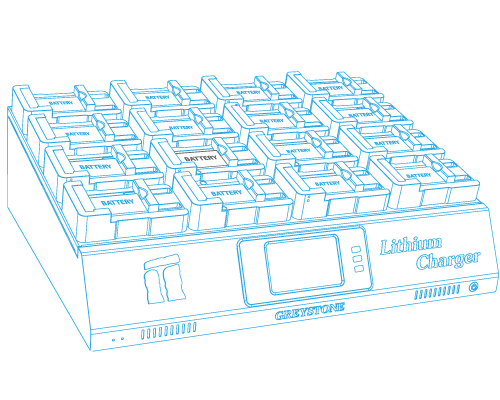

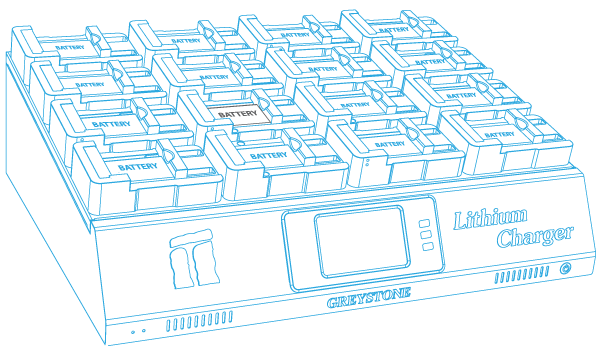

Lithium Charger

- Quick Test: Test and report the results of battery status (State Of Health - SoH) within 3 minutes.

- Long Test: Test and report SoH results of the batteries in approximately 3 hours with high accuracy. Charge:

- Charge all kinds of Li-ion batteries with Designed Capacity up to 6000mAh.

- Discharge: Discharge all kinds of Li-ion batteries with Designed Capacity up to 6000mAh.

- Refurbish: including the process of charging and discharging the batteries several times in order to increase the operational capability of the batteries that were not used for a long time.

- Analyze: Analyze the characteristics of batteries in order to create profiles for QuickTest function.

- Jump-Start: Activate the battery voltage was down.

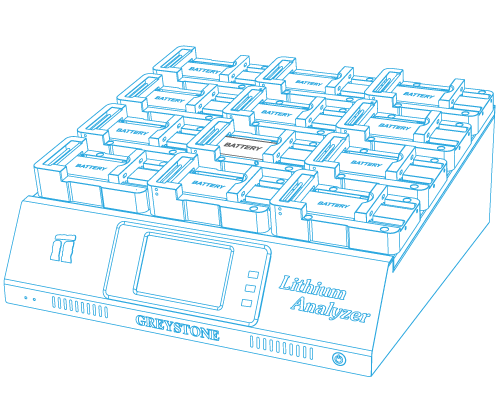

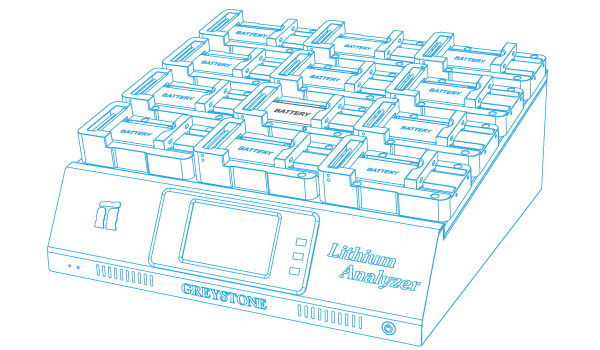

Lithium Analyzer

- Quick Test: Test and report the results of battery status (State Of Health - SoH) within 3 minutes.

- Long Test: Test and report SoH results of the batteries in approximately 3 hours with high accuracy. Charge:

- Charge all kinds of Li-ion batteries with Designed Capacity up to 6000mAh.

- Discharge: Discharge all kinds of Li-ion batteries with Designed Capacity up to 6000mAh.

- Refurbish: including the process of charging and discharging the batteries several times in order to increase the operational capability of the batteries that were not used for a long time.

- Analyze: Analyze the characteristics of batteries in order to create profiles for QuickTest function.

- Jump-Start: Activate the battery voltage was down.

PCB Tester

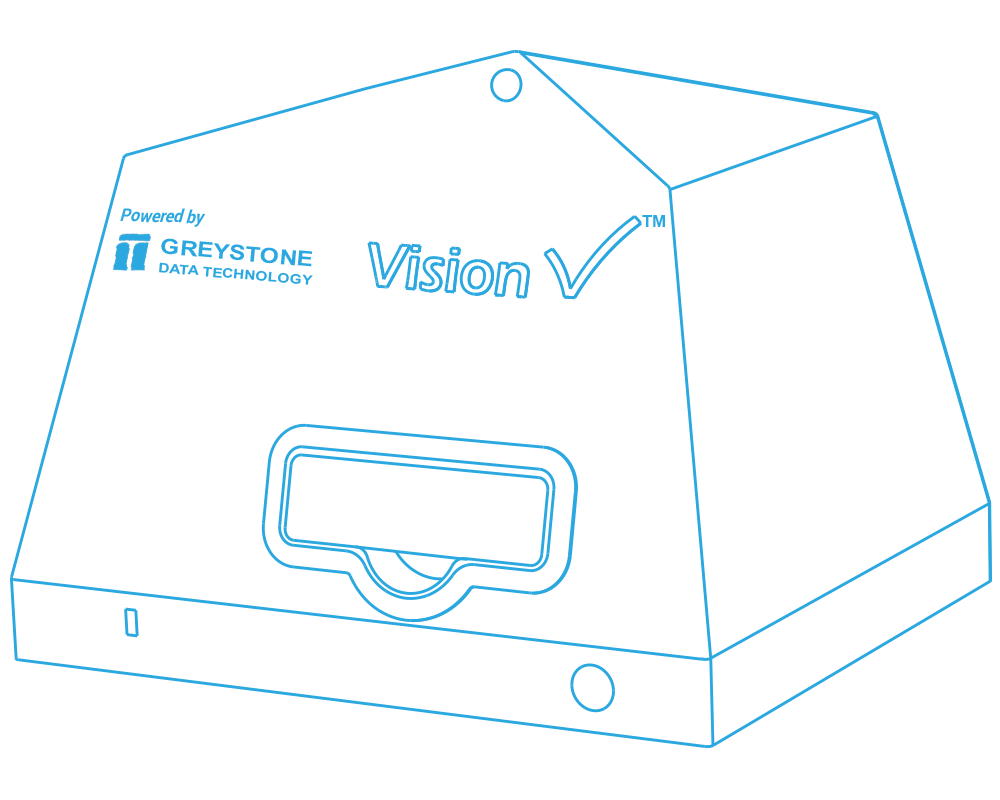

VisionCheck

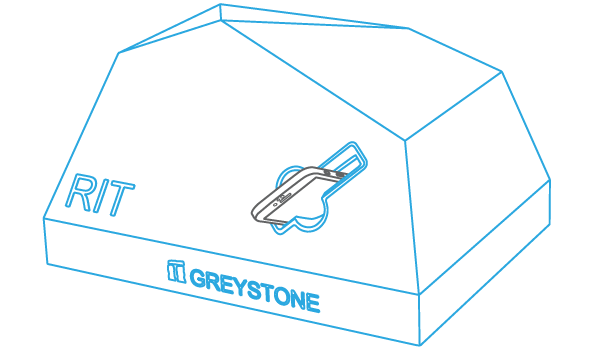

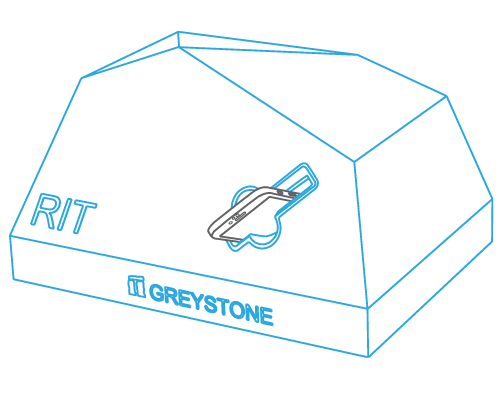

Relying on powerful OCR algorithms to convert captured images to machine text and data. The RIT machine receives device information without requiring connection to a computer or the device to power on. This innovative system is capable of reading the Human readable information on the back of a mobile device, then parsing the information out to a computer in machine language. You no longer need to read an IMEI on the back of a device and type it into a computer. The data is analyzed and presented in industry accepted formats. The RIT system also reads bar codes in any orientation adding to the versatility of this system. You may even connect a mobile device to the KIT system to read the internal information. The KIT has barcode scanner emulation with programmable keystroke output via USB connection. The KIT provides complete productivity reporting, which is available on our cloud based Dashboard.

Receiving Imaging Technology

Relying on powerful OCR algorithms to convert captured images to machine text and data. The RIT machine receives device information without requiring connection to a computer or the device to power on. This innovative system is capable of reading the Human readable information on the back of a mobile device, then parsing the information out to a computer in machine language. You no longer need to read an IMEI on the back of a device and type it into a computer. The data is analyzed and presented in industry accepted formats. The RIT system also reads bar codes in any orientation adding to the versatility of this system. You may even connect a mobile device to the KIT system to read the internal information. The KIT has barcode scanner emulation with programmable keystroke output via USB connection. The KIT provides complete productivity reporting, which is available on our cloud based Dashboard.